Colorado Sheet Metal Workers Apprenticeship Program

As an Apprentice in the Colorado Sheet Metal Workers’ Apprenticeship Program, you will earn a good salary while learning your trade – a salary that increases as your skills and knowledge increase. You pay no tuition costs and no fees for the training and education, you will receive books and other educational material and college credits, completely free of charge, all while getting paid. You will learn from instructors who work in the Sheet Metal Industry alongside you, and you will put everything you learn to work right away—your career begins at the same time your apprenticeship begins. Finally, you will graduate with absolutely zero student loan debt, certified to work in multiple high-demand career specializations in the Sheet Metal Industry.

To apply for the Colorado Sheet Metal Workers’ Apprenticeship Program fill out the Apprentice Application at the link to the right.

SMACNA Colorado and SMART Local 9 support the the Colorado Sheet Metal Workers’ Joint Apprenticeship & Training Committee and its Sheet Metal Workers’ Apprenticeship Program. The Apprenticeship Program is a highly competitive Earn While You Learn program that trains Sheet Metal Workers in every facet of the industry and connects them with one of our 50+ Contractor Members for employment during training. So, here is how it works:

Most Apprentices start off working as Material Handlers for a few months before being accepted into the Apprenticeship Program. This helps get you working and earning a living while gaining some experience in the field before starting the full Apprenticeship Program.

Applicants to be Material Handlers and Apprentices apply online at the Apprentice Application link provided above. Once you submit your application, you will be contacted by SMACNA Colorado Talent Acquisition Coordinator John Stone to guide you through the process. In order to be considered for acceptance into the program, you must be at least 17 years old, have completed your high school diploma or have your GED, have a valid driver’s license, and proof of age and eligibility to work in the US. We also require that all Applicants take the ASVAB test, which we coordinate and schedule for you. The final step is a Candidate Interview with the JATC Directors. Candidates are then ranked on a scale of 1 to 100, and the top Candidates are accepted into the Apprenticeship in the Spring and in the Fall.

To apply for the Colorado Sheet Metal Workers’ Apprenticeship Program fill out the Apprentice Application at the link to the right.

The Colorado Sheet Metal Workers Apprenticeship Program has 3 Training Centers, each of which are outfitted with state-of-the-art equipment and learning tools. From each full Sheet Metal Shop, to each Service Lab, to each CAD Lab, we ensure that you have the best training in the industry.

Denver Training Center — 1515 W 47th Ave Denver CO 80211

Colorado Springs Training Center — 1420 Quail Lake Loop Colorado Springs CO 80906

Grand Junction Training Center — 2980 Gunnison Ave Grand Junction CO 81504

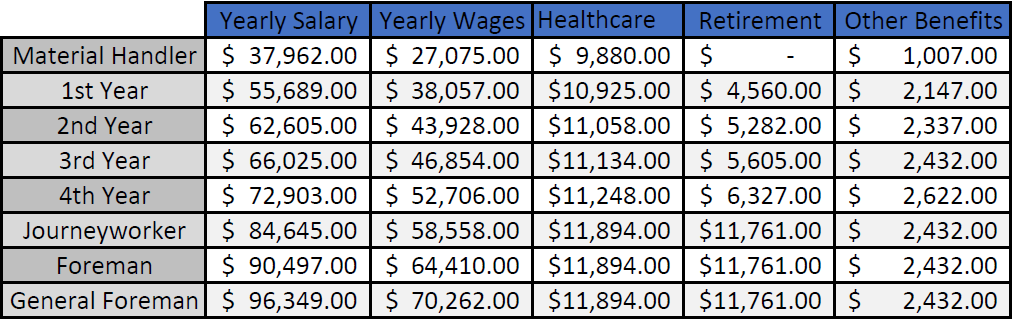

Starting Apprentice Wages+Benefits

You will make highly competitive wages, coupled with a Local Pension, a National Pension, and a 401k, along with fully-employer-paid full coverage healthcare for the entire family, and a generous vacation fund. That’s $0.00 out of pocket on health insurance premiums, $0.00 out of pocket on retirement programs, and $0.00 out of pocket for the education and training that will put you at the top of the field.

*Above is the Appendix A Wage Matrix which applies to the City & County of Denver, Arapahoe County, Boulder County, Jefferson County, Adams County, Douglas County, Larimer County, and the City & County of Broomfield. Some specialty shops have an independently negotiated Wage Matrix. For Appendix B Wage Matrix and the Western Slope In-Town and Out-of-Town Wage Matrix, scroll to the bottom of the page.

To apply for the Colorado Sheet Metal Workers’ Apprenticeship Program fill out the Apprentice Application at the link to the right.

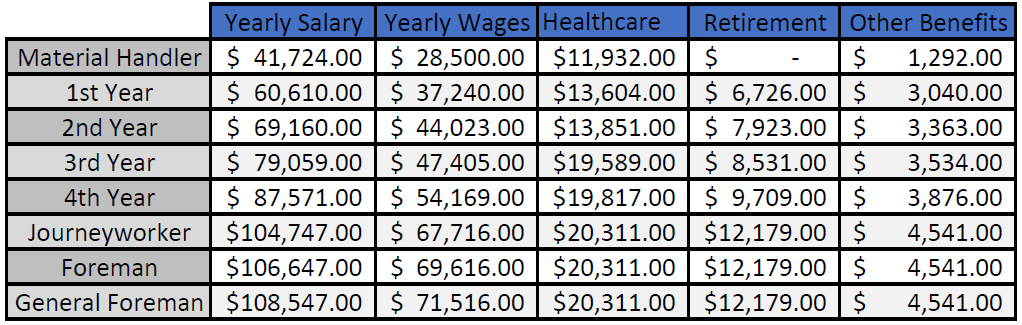

Total Compensation Package

Your Total Compensation Package as a 1st Year Apprentice will put you well above the average salary of most college graduates, and it just increases from there. Once you graduate from the Apprenticeship Program and become a Certified Journeyworker, you will make over $100k per year in total compensation, to start. Many of our Contractors recruit their Foremen and General Foremen from among their own Journeyworkers, which means higher salary and more career advancement options for you.

To apply for the Colorado Sheet Metal Workers’ Apprenticeship Program fill out the Apprentice Application at the link to the right.

Career Paths

There are many Career Paths for you both during your Apprenticeship and after your graduate as a Journeyworker. Whether you want to work outside on different jobsites, inside in a shop, at a desk behind a computer, or in the boardroom, there is a Sheet Metal Industry Career Path for you, and the Apprenticeship Program will get you there. Take a look at some of our Career Paths below.

Commercial HVAC

HVAC stands for heating, ventilation, and air conditioning. In this field, you will work on high-volume mechanical systems. These systems deliver heated and cooled air to commercial buildings such as schools, hospitals, airports, factories and office buildings. You’ll work in an exciting environment with dozens of other trade workers, creating something that is long lasting and enhances the quality of life for many people.

Opportunities in this field include:

- Installer

- Service technician

- Supervisor

- Testing, Adjusting, and Balancing (TAB) technician

- Indoor Air Quality (IAQ) technician

- Energy management technician

- Commissioning agent

- Project manager

- Detailer

ARCHITECTURAL METAL

Architectural Metal is a combination of technical skills and artistry. Architectural Metal Workers specialize in fastening and joining, managing expansion and contraction, sealing, and controlling moisture to ensure the appearance and durability of buildings. Architectural Metal Workers spend a good part of their career working at large commercial/industrial sites or residential jobs.

Opportunities in this field include:

- Installer

- Fabricator

- Solderer

- Crew Leader

- Designer

- Project Manager

- Customer Sales and Service

DETAILING & SKETCHING

Sheet Metal Detailing, also known as Sketching, is often thought of as CAD (Computer-Aided Drafting). A Certified Detailer is a skilled commercial HVAC trade person who will advance to provide coordination between the Hardware Fabricators and the Installers from various trades. Detailers work with project documents, plans, and specifications, take field measurements, and create 3-D coordination digital drawings, along with Building Information Modeling (BIM).

Opportunities in this field include:

- Detailer

- Customer Service Representative

- Project Manager

- Contractor

SERVICE & REFRIGERATION

Almost everything we do indoors depends on a working heating and cooling system. These systems make buildings comfortable and safe. Demand for skilled technicians in this specialized field is high. Service & Refrigeration Workers work on a variety of job sites. They install and test systems to ensure that they are operating safely and efficiently. The work is always exciting and challenging and Service & Refrigeration Workers are always in demand.

Opportunities in this field include:

- Service Technician

- Fabricator

- System Evaluator

- Energy Consumption Manager

- Service Manager

INDUSTRIAL SHEET METAL

Industrial Sheet Metal Workers work on large-scale projects, custom projects, or large shop-built modules. Industrial Sheet Metal Workers make the machines used in automotive assembly and food processing plants. They can choose to work on specialized installations almost anywhere in the world. The projects Industrial Sheet Metal Workers work on last for years and enhance the quality of life for many people.

Opportunities in this field include:

- Custom Fabricator

- Grinder & Finisher

- Plasma Cutter Operator

- Field Installer

- Field Foreman

- Shop Foreman

- Estimator

- Project manager

- Shop owner

TESTING, ADJUSTING & BALANCING (TAB)

Testing, Adjusting, & Balancing (TAB) is an important part of air and water delivery systems. TAB Technicians make sure that air and water in heating and air conditioning systems are delivered efficiently, quietly, and safely throughout a building. TAB technicians are responsible for working on air and water delivery systems to meet the specifications outlined by the design engineer.

Opportunities in this field include:

- Energy Management

- Indoor Air Quality

- Building Systems Commissioning

- Sound & Vibration Testing

- Fire Life Safety Control Systems

- HVAC Installation or System Controls

- System Design

- Project Management or Facility Management

- Clean Room Work or Certification

RESIDENTIAL HVAC

Residential HVAC Workers install and service complete Residential HVAC Systems. They install ductwork for a wide variety of residences including single-family homes, town homes and apartment buildings. Residential HVAC Workers also work on duct systems for existing buildings to remodel, upgrade, or troubleshoot. Most of this work is done in the field.

Opportunities in this field include:

- New construction installer

- Residential finish installer

- Retrofit technician

- Residential services technician

Fabrication

Working in a Mechanical Contractor’s shop offers many unique opportunities. Fabrication workers work with a wide variety of materials and learn fabrication techniques from the experts. Many Commercial HVAC Fabricators also install the products they create. Welding, Autocad, CNC, and Quality Control are all part of everyday Fabrication techniques. Fabrication Workers work in the shop to make finished components for construction projects such as:

- Spiral Duct Components

- Square Duct Components

- Spin-Ins

- All other parts and fittings as necessary

- Custom fabrication

- Plasma and Laser cutting

- CNC automation

- Pre installation assembly

Welding

Welding is part of many industries. Sheet Metal Workers have the benefit of working with a wide variety of materials in many different situations. Our Welders are trained and certified in our AWS Testing Lab, by AWS Certified Instructors.

Welders work in both field and shop to produce and install:

- Grease ducts

- Stainless steel hoods

- Stainless steel exhaust ducts

- Form an understanding of metal composition

- Learn multiple fabrication techniques

- Work with a wide range of materials – iron, copper, titanium, stainless steel, aluminum, and plastic

- Work in various locations – underwater, skyscrapers, power plants, kitchens, fabrication facilities, semi-conductor plants, nuclear power plants, food processing plants

- Learn to read and intemperate blueprints

Foreman

Leadership opportunities exist for those that are ready to step up. All Apprentices are taught skills to help them become a Job Foreman. The excitement of leading a team through the daily demands comes with many rewarding benefits. Foremen get the chance to shape craftsmen, control quality, and of course make more income. Job Foremen lead a team of Sheet Metal Industry Professionals in:

- On-Site Construction Management

- Shop Division Direction and Management

- Apprentice Development

- Coordination of material, installation, and manpower

- Quality Control

- Safety Management

- Daily record keeping

- Innovate and Initiate problem-solving solutions

- Implement company policies and procedures

- Budget review and compliance

General Foreman

If you like to control your future, strive to become a General Foreman. Leadership skills are taught throughout your sheet metal career, this is the pathway that puts them to the greatest use. Progression from Apprentice to Journeyman, to Foreman are the pathway to holding the title of General Foreman. General Foremen managing entire jobsites of Sheet Metal Industry Professionals

- Construction Project Management

- Full Shop Management

- Leadership Development

- Oversight of all Foreman responsibilities

- Manage multiple Foreman and Projects

- Coordinate Projects at Bid, Design, and Implementation Levels

- Communication with Architects, Engineers, General Contractors, and Owners

- Coordinate material and equipment delivery/installation

- Review and maintain proper labor rates and crew size

Project Manager

Project Managers serve a variety of purposes in the construction industry. Most of the day to day business of a construction project goes through a Project Manager. Construction cost, progression, scheduling, and design changes are just a few elements of this highly sought career. Project Managers interact with business leaders, architects, engineers, and jobsite supervision. Higher salary, bonuses, and flexible schedules are some of the benefits of a dedicated and proven Project Manager. Construction Project Managers are an important part of all commercial projects.

Contractor

When working for yourself is the goal, consider owning a Sheet Metal Contracting business. Whether you want be a single person company or become a major corporation, going through a Union Apprenticeship is a great place to start. You will learn from industry leaders and get the support of an established labor/management relationship. Education is available to help you achieve your goals and growth is determined by your ambition. As a Contractor, you will own your own business employing Sheet Metal Industry Professionals. Many SMACNA Colorado Member Contractors are owned by Sheet Metal Industry Professionals who started as Apprentices in our program and now own their own businesses.

To apply for the Colorado Sheet Metal Workers’ Apprenticeship Program fill out the Apprentice Application at the link to the right.

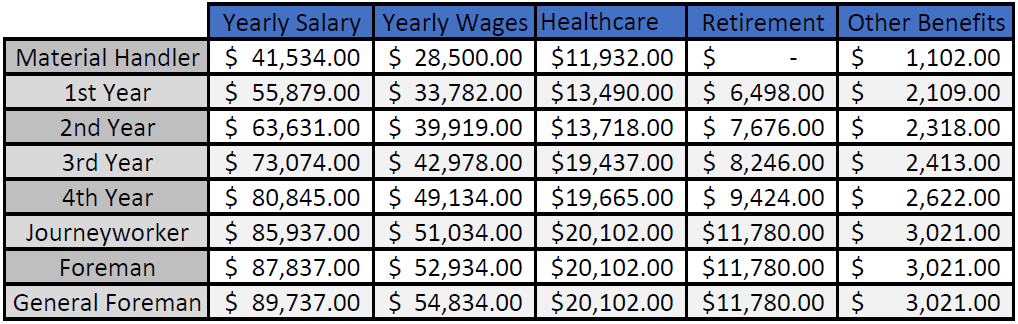

Appendix B Wage Matrix

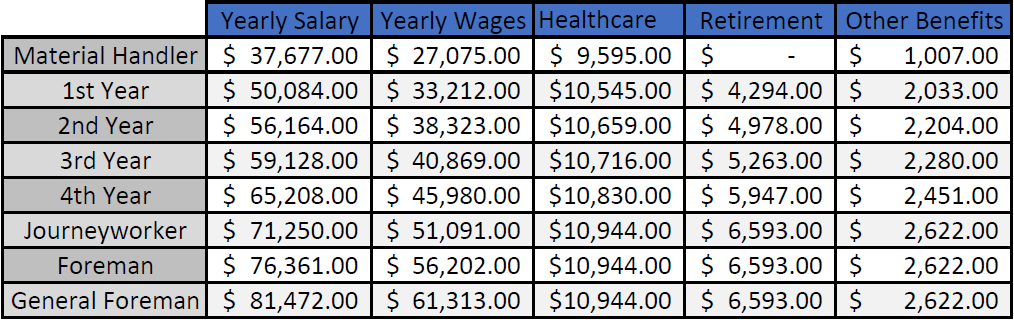

Western Slope In-Town Wage Matrix